A small team of dynamic, young engineers are about to change the world of prosthetics forever. Meet the brains behind Open Bionics. If you were given some Lego and a couple of basic motors could you design and build a makeshift floor cleaner? Joel Gibbard could. When he was seven years old! Impressive though the rudimentary machine was, it was merely Joel’s first step on a journey that, 18 years later, has brought him to the brink of manufacturing a bionic hand that can be 3-D printed in a fraction of the time – and at a fraction of the cost – of current prosthetic devices.

Open Bionics, the company that he set up with business partner Samantha Payne just a few years ago, has successfully engineered a fully-functioning prototype that could be on sale by the end of the year for as little as £2,000. Quick to make, easy to use, and with the ability to replicate movement in all 24 joints of a human hand, the prosthetic could prove revolutionary for amputees and people born without hands.

Punching above their weight

The prosthetic is made from a flexible but incredibly hard-wearing plastic. Shark-strength fishing wire runs through the finger joints to motor modulators. Sensors in the forearm, meanwhile, are connected to a circuit board the size of two postage stamps, which transforms muscle impulses into six different movements including full grip, a finger and thumb pinch, a three-finger tripod grip, and a point.

“There have been big jumps along the way,” says Joel, who attracted £40,000 start-up funding after leaving university to create low cost prosthetics. “Everything worked on our first model but it only lasted a few hours. Later versions broke down for one reason or another, but now the hand will move how the amputee wants it to. The latest iteration has been used as a demonstration model all around the world for the last six months, so has taken more than its fair share of knocks, and it’s still going strong.”

Our future in ther hands

Tests have proved the latest model can easily hold 5kg shopping bags, while the joints have gone through 200,000 cycles of movement without an issue. But perhaps the most exciting aspect of this project is the fact that it takes less than a week to scan a socket fitting and print a new hand (compared to current waiting times of several months), while the cost will be in the region of £2,000 rather than the eye-watering £50,000 price tag of some of the market-leading prosthetics.

And despite the cutting edge nature of Open Bionics’ product, the company has made its design and technology ‘open source’ which means anyone can share and use the technology without fear of facing a hefty lawsuit.

It is an incredibly bold and inspiring attitude, and one that will accelerate development and ensure that amputees will not be priced out of the new device.

“We want it to be as accessible as possible,” says Joel, a 25 year old who built his first robot out of scrap parts as a teenager before creating a robotic hand for his final year project at Plymouth University. “We are obviously driven by making this happen as an engineering and technological challenge, but we also want as many people as possible to benefit from it as quickly as possible.

“Some incredible technology already exists that could change lives completely, but it is often prohibitively expensive. We see our job as making this technology accessible to everyone. We are starting with hands but see this progressing into legs and even exoskeletons in the future.”

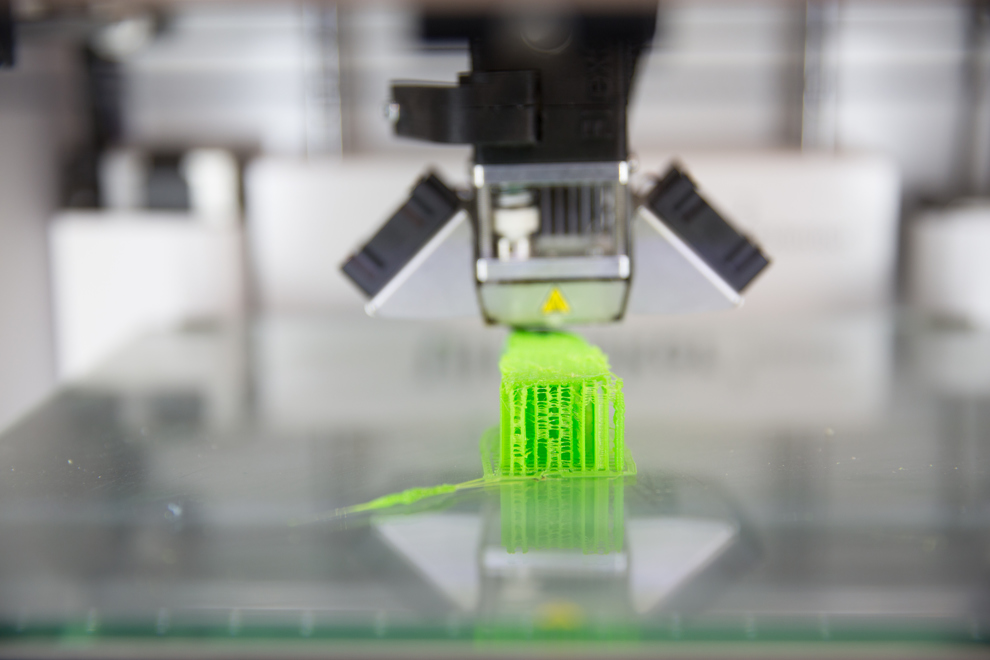

Development starts with a sketched design, which becomes increasingly detailed and intricate as each new component and interaction is tested on the way to finding the most efficient mechanisms that can be easily replicated on the company’s six 3-D printers.

Open Bionics’ expansion has been fuelled by a series of grants, including support from the Disney Accelerator Programme and the James Dyson Award for innovation, as well as by a £125,000 sum from an Intel-organised Dragon’s Den-style competition in San Francisco.

“We had to pitch to a panel of seven people in front of an audience of about 200 while the event was streamed live, so it was incredibly nerve-wracking,” says Samantha Payne, Open Bionics’ 24-year-old co-founder and Chief Operating Officer (pictured right). “I think everyone saw the business opportunity but also appreciated that this has the potential to impact on millions of people and do real social good.

“Investors can see the opportunity but some ask why we’re going to sell the hand so cheaply when we could bump the price up to £25,000 and it would still cost less than the competition. But we don’t think like that. We have spoken to lots of trauma patients, many of whom have experienced deep depression after losing a hand. One amputee even said he felt suicidal after experiencing what he described as ‘the shame of not being able to do the everyday activities’ he once did with ease. He told us his life changed when he was given a fully-articulated hand. Suddenly, he had a device that enabled him to tie his shoelaces again.

“That was obviously very useful, but because it was shaped like a human hand, and the fingers moved like the fingers he had lost, he said he felt whole again. Having a bionic hand that looks human can make a big difference. Until now, the issue has been being able to afford one.”

From home to hope

Open Bionics is now based at the Bristol Robotics Laboratory, an incubator project at the University of the West of England, where groundbreaking developers are perfecting advanced drones and medical robots. But the journey started at the Gibbard family home where Joel and his brother were inspired by their architect father’s ability to engineer complex models from Meccano.

“Dad would build rockets that were bigger than me, and I remember him once creating a model of the Space Shuttle and launch pad without any drawings or instructions,” says Joel. “I was brought up with an interest in robotics and started messing about with bits and piece around the house, building robotic hands for fun way before I went to university. What’s not to love about robotics? It’s a combination of all engineering disciplines; mechanical, electronic and software all rolled into one, with everything having to work at the same time. I find that fascinating.”

That fascination has obviously paid off as Open Bionics approaches product registration and clinical trials.

“We’re not sure how long that will all take because we have never been through the process before and we’re a small team of five, but we’re aiming for a product launch at the end of this year,” says Samantha. “Our engineering team could be earning a lot more money working for huge multi-national companies, but they are all here because they’re dedicated to making this happen. Our approach is fresh, and the potential to help many, many people is driving us all forward.”

We can help

We are dedicated to assisting serving and ex-Service men and women who have suffered life-changing limb loss or the use of a limb, an eye or sight. We support these men and women in their communities throughout the UK. Click the link below to find out the different kinds of support we offer.

Get Support

Leave a comment

Join fellow Members and supporters to exchange information, advice and tips. Before commenting please read our terms of use for commenting on articles.